Device description

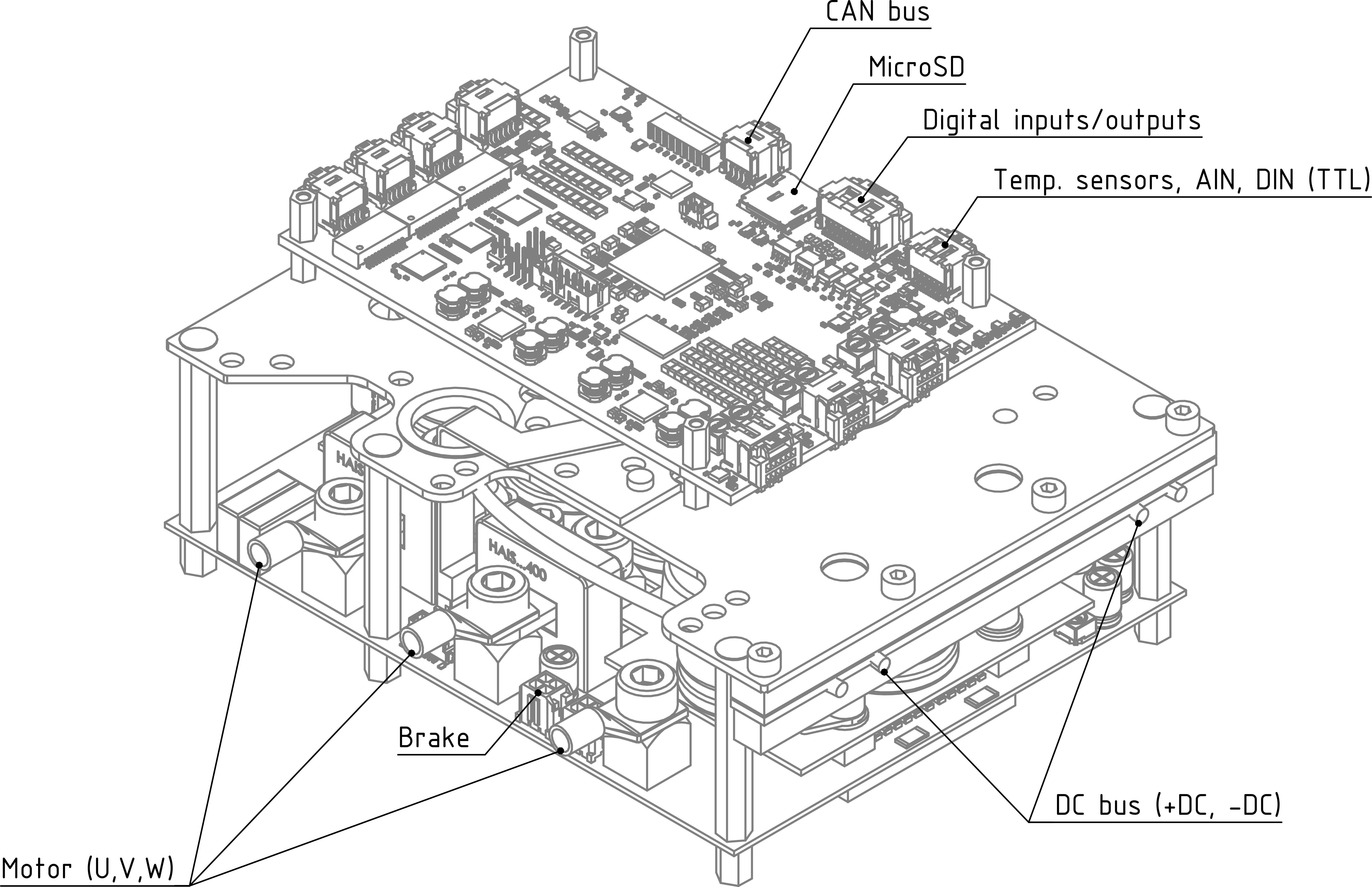

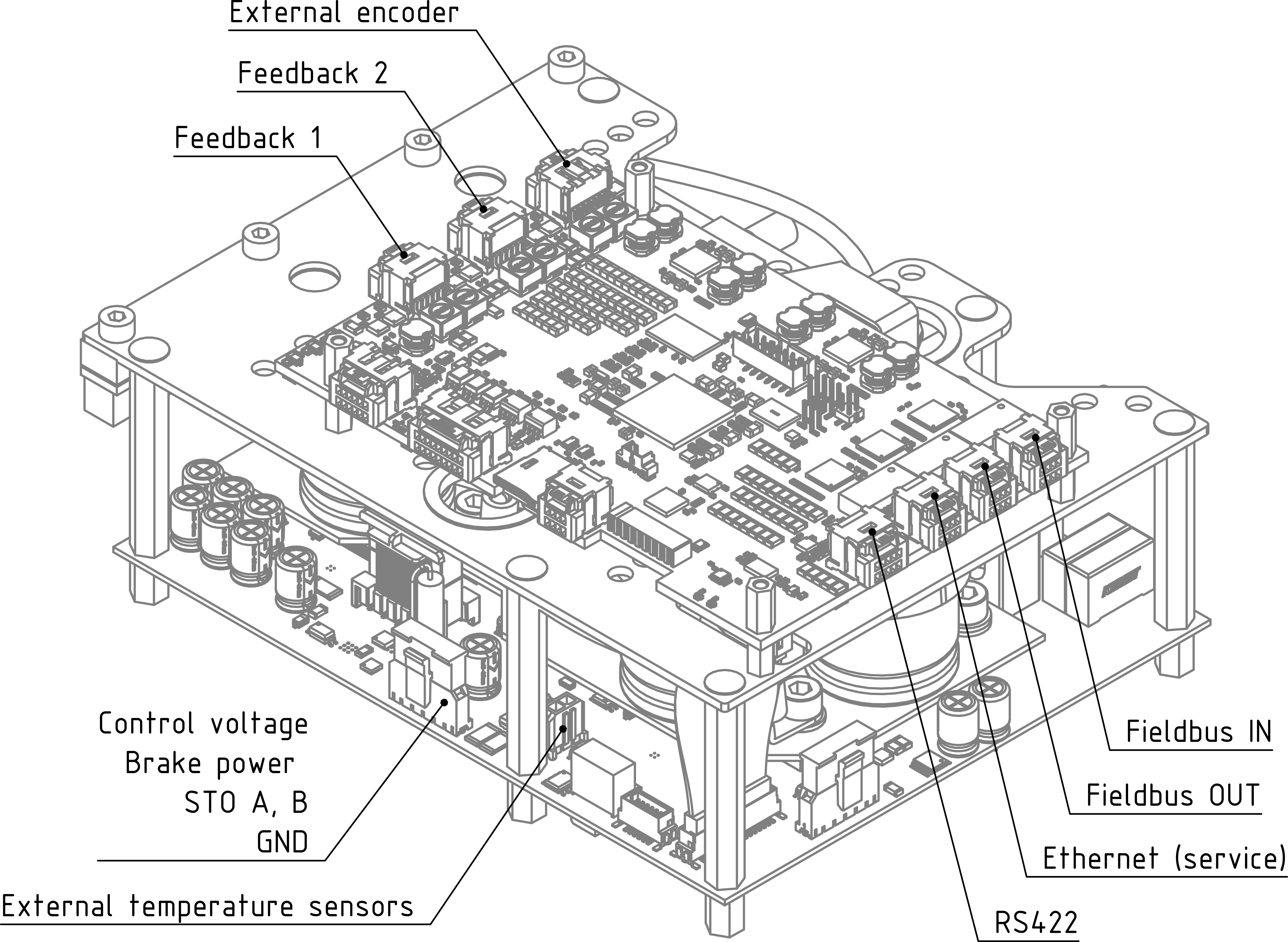

3D view¶

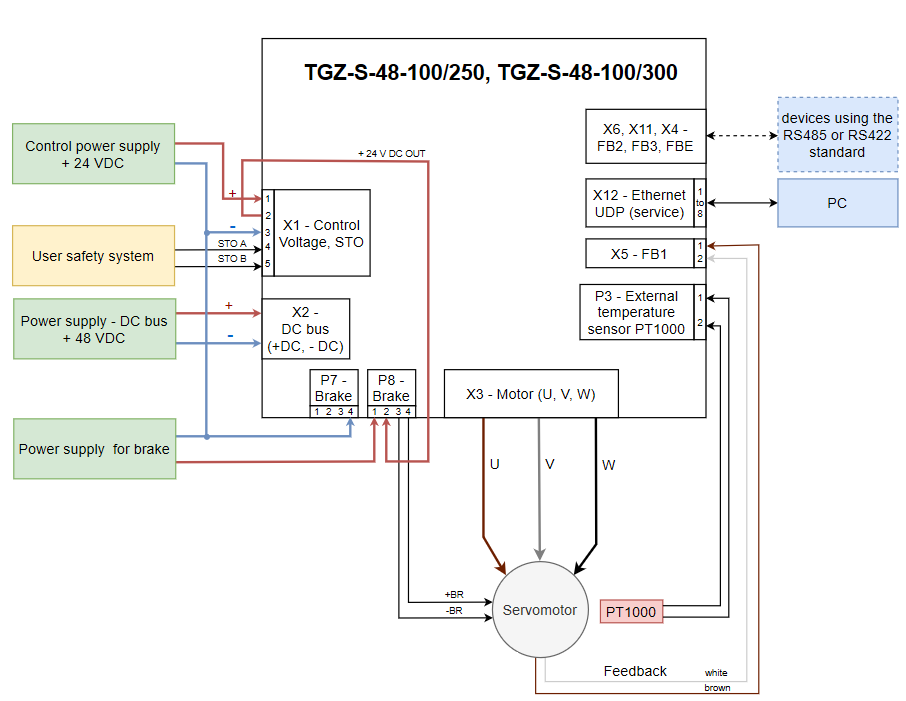

Block diagram with connection of main interfaces¶

Note

The external temperature sensor PT1000 is used to measure the motor temperature.

Description of communication, input/output and control¶

Communication interfaces¶

- Ethernet 100/1000 Mb/s with UDP protocol, designed for parameter recording, monitoring, testing, but also online control;

- CAN bus protocol can be modified according to customer requirements;

- Ethernet 100/1000 Mb/s with optional protocol, programmed in the gate array and designed for connection of fast industrial buses for real-time control. Currently, this interface is equipped with the EtherCAT protocol (only for standard firmware); according to customer requirements it can be modified to another type of protocol.

- RS422 or RS485, data transfer via unused servomotor feedback interface. It can be used for communication with devices based on RS422 or RS485 standard (encoder, gyro, master controller, other system, etc.). This interface enables high-speed communication up to 20Mbit/s.

Inputs / outputs¶

The built-in TGZ servo amplifiers have 8 isolated digital inputs, 3 digital inputs, 6 isolated digital outputs, 1 analog input and 2 PT1000 thermistor inputs implemented. It is possible to control these inputs and outputs using a user program (C language):

| I/O | Type | Count | Value |

|---|---|---|---|

| input | analog | 1 | 0-10 V |

| input | thermistor | 2 | standard PT1000 |

| input | digital | 3 | 0-30 VDC (0-0.8 V low / 2.4-30 V high) |

| input | isolated digital | 8 | 0-24 VDC (0-10 V low / 13-24 V high), 10 mA |

| output | isolated digital | 6 | 5-24 VDC, 300 mA / max. output |

The servo amplifier has four feedback connectors, which have a wide range of uses. In addition to motor feedback, they can be used to connect devices operating on the principle of the RS422 or RS485 standard.

| Type | Standard | Interface | Examples of Possible Connected Devices |

|---|---|---|---|

| FB1 | RS422/RS485 | Hiperface DSL, EnDat 2.2, SSI, BISS | Absolute magnetic/optical encoder, incremental magnetic/optical encoder with Hall sensors 2, gyroscope |

| FB2 | RS422/RS485 | Hiperface DSL, EnDat 2.2, SSI, BISS | Absolute magnetic/optical encoder, incremental magnetic/optical encoder with Hall sensors 2, gyroscope |

| FE1 | RS422/RS485 | Hiperface DSL, EnDat 2.2, SSI, BISS | Absolute magnetic/optical encoder, incremental magnetic/optical encoder with Hall sensors 2, gyroscope |

| FB31 | 2 × full-duplex RS422 | - | Control system |

- Hiperface DSL – digital communication, sensors are manufactured with a resolution of 15 to 24 bits per revolution (multi-speed design – 4,096 revolutions). This type of feedback is used for motors with a single connector or cable.

- EnDat 2.2 – digital communication, sensors are manufactured with a resolution of 18 to 25 bits per revolution (multi-speed design – 4,096 revolutions).

- SSI – encoders with synchronous system interface.

- BISS – sensors with BISS-C protocol.

Control¶

TGZ servoamplifiers can be controlled:

- digital control via EtherCAT, CAN-bus (torque, speed, position profiles, etc.) and via Ethernet UDP protocol;

- via user program (language C) – digital inputs, analog voltage, etc.

Connectors¶

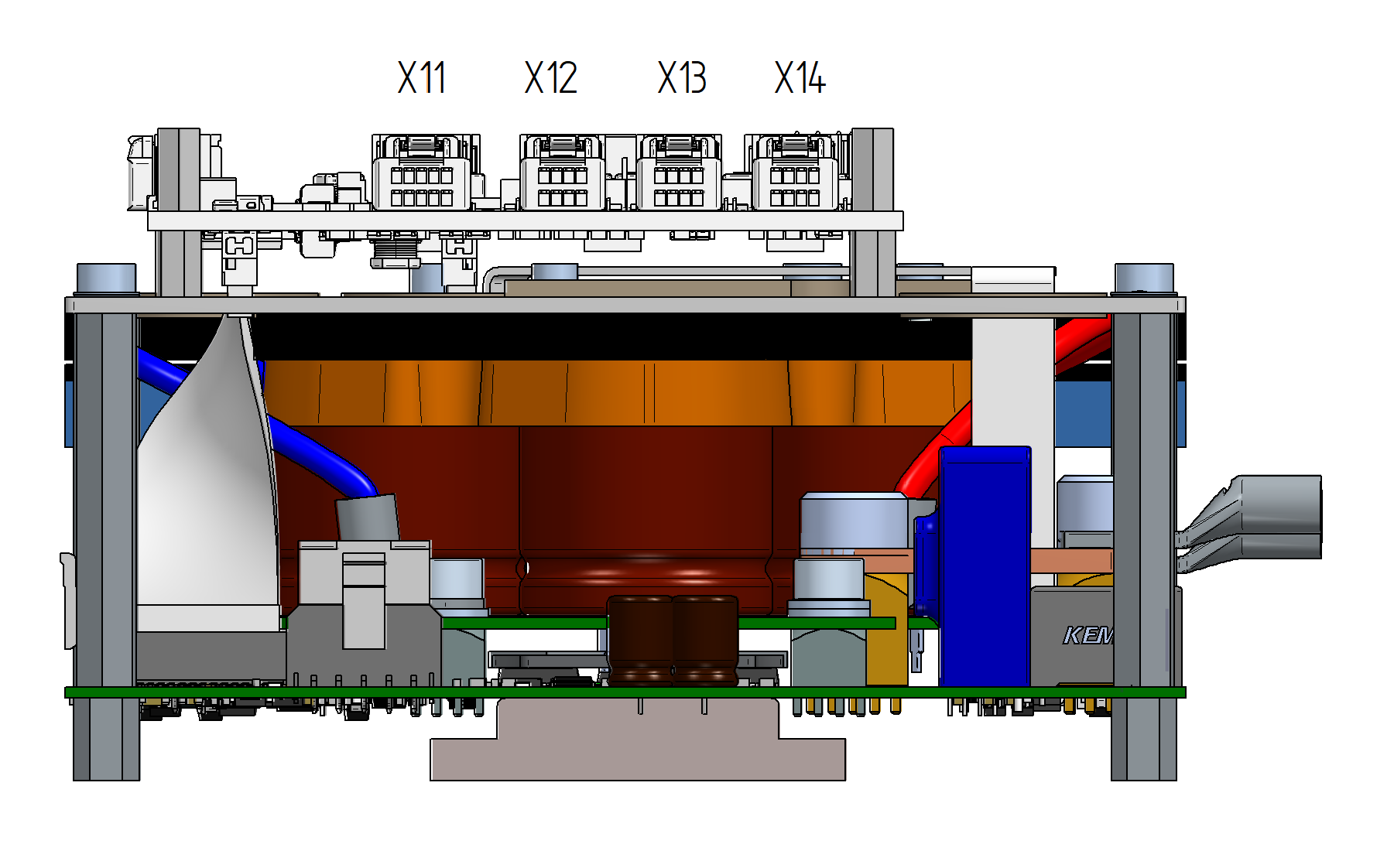

View of the ENET/ECAT side¶

-

X11 - Feedback 3 - RS422

-

Molex ClikMate 5031491000 - recommended crimping contacts Molex 502579 3

pin # Marking Description 1 TxD- RS422 #1 Transmit data - 2 TxD+ RS422 #1 Transmit data + 3 RxD- RS422 #1 Recieve data - 4 RxD+ RS422 #1 Recieve data + 5 +12 VDC OUT output +12V 6 GND Common GND 7 TxD+ RS422 #2 Transmit data + 8 TxD- RS422 #2 Transmit data - 9 RxD+ RS422 #2 Recieve data + 10 RxD- RS422 #2 Recieve data - Warning

When using this type of feedback, make sure you are using the appropriate TGZ firmware that supports these features.

-

X12 - Ethernet UDP - service

-

Molex ClikMate 5031490800 - recommended crimping contacts Molex 502579 3

pin # Marking Description 1 DD+ T568B pair D positive (Bn-Wh) 2 DD- T568B pair D negative (Bn) 3 DC- T568B pair C negative (Bl-Wh) 4 DC+ T568B pair C positive (Bl) 5 DB- T568B pair B negative (Gn) 6 DB+ T568B pair B positive (Gn-Wh) 7 DA+ T568B pair A positive (Or-Wh) 8 DA- T568B pair A negative (Or) -

X13 - EtherCAT 2 - Fieldbus out

-

Molex ClikMate 5031490800 - recommended crimping contacts Molex 502579 3

pin # Marking Description 1 DD+ T568B pair D positive (Bn-Wh) 2 DD- T568B pair D negative (Bn) 3 DC- T568B pair C negative (Bl-Wh) 4 DC+ T568B pair C positive (Bl) 5 DB- T568B pair B negative (Gn) 6 DB+ T568B pair B positive (Gn-Wh) 7 DA+ T568B pair A positive (Or-Wh) 8 DA- T568B pair A negative (Or) -

X14 - EtherCAT 1 - Fieldbus in

-

Molex ClikMate 5031490800 - recommended crimping contacts Molex 502579 3

pin # Marking Description 1 DD+ T568B pair D positive (Bn-Wh) 2 DD- T568B pair D negative (Bn) 3 DC- T568B pair C negative (Bl-Wh) 4 DC+ T568B pair C positive (Bl) 5 DB- T568B pair B negative (Gn) 6 DB+ T568B pair B positive (Gn-Wh) 7 DA+ T568B pair A positive (Or-Wh) 8 DA- T568B pair A negative (Or)

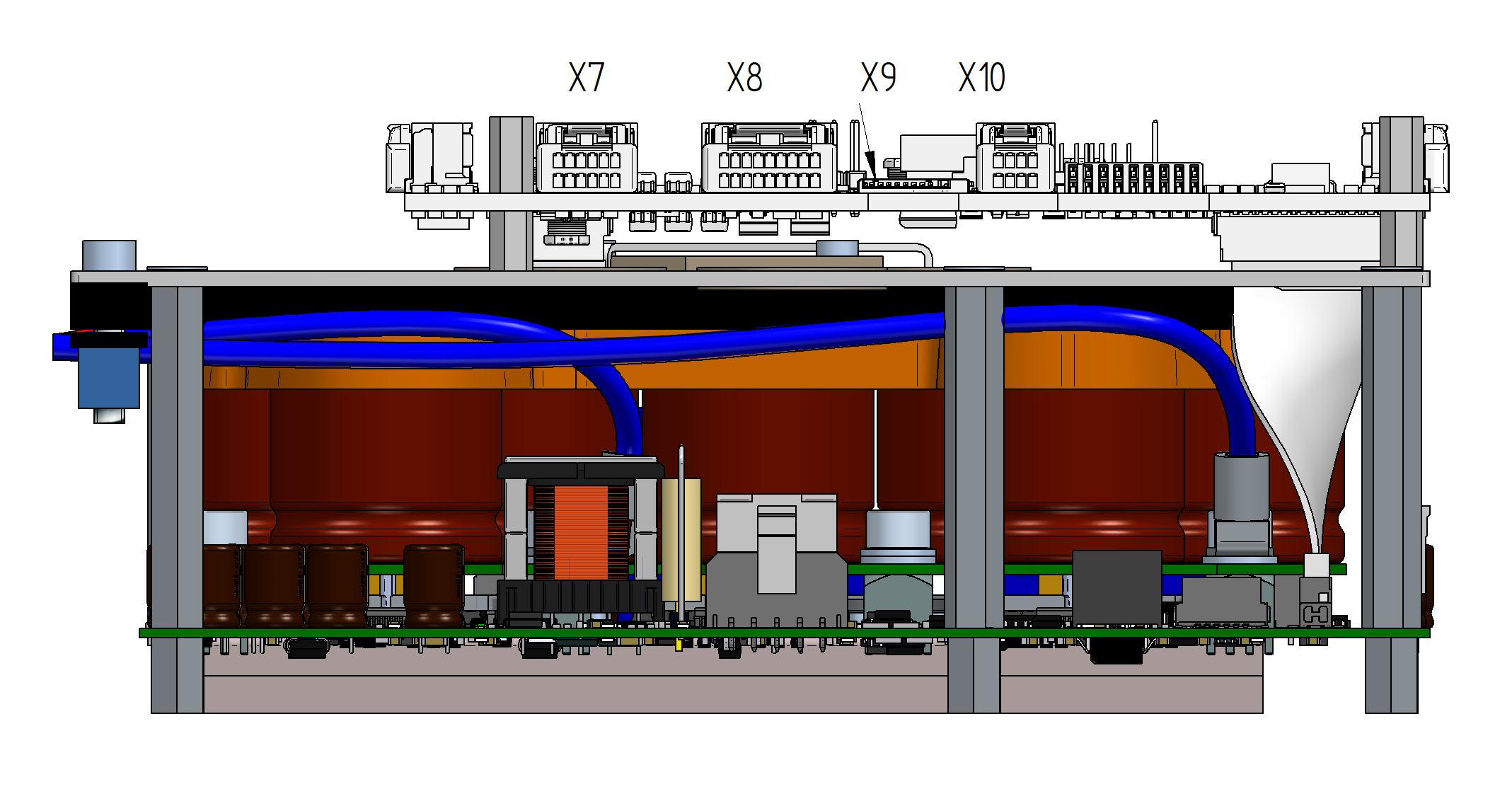

View of the CAN/IO/SD Side¶

-

X7 - Digital inputs + Analog inputs

-

Molex ClikMate 5031491200 - recommended crimping contacts Molex 502579 3

pin # Marking Description 1 AIN Analog input 0-10V 2 AGND Analog ground 3 PT1000_2+ input for 2. PT1000 4 PT1000_2- input for 2. PT1000 5 PT1000_1+ input for 1. PT1000 6 PT1000_1- input for 1. PT1000 7 DITTL1 Dig. input 5-30V 8 DGND Digital ground 9 DITTL2 Dig. input 5-30V 10 DGND Digital ground 11 DITTL3 Dig. input 5-30V 12 DGND Digital ground Warning

Direct PT1000 inputs of X7 pins 3-6 are only available on control board from batch supplied after 06-2024 onwards. Older versions of the device have standard AIN1, AIN2 and AIN3 on pins 1-6 of X7. For further details of the previous device properties please see older version of this manual.

-

X8 - Digital I/O

-

Molex ClikMate 5031491800 - recommended crimping contacts Molex 502579 3

pin # Marking Description 1 DI1 Digital input isolated no. 1 2 DI2 Digital input isolated no. 2 3 DI3 Digital input isolated no. 3 4 DI4 Digital input isolated no. 4 5 DI5 Digital input isolated no. 5 6 DI6 Digital input isolated no. 6 7 DI7 Digital input isolated no. 7 8 DI8 Digital input isolated no. 8 9 GNDIO Isolated power ground 10 GNDIO Isolated power ground 11 VDDIO Isolated PSU DO 24V 12 VDDIO Isolated PSU DO 24V 13 DO1 Digital output isolated no. 1 14 DO2 Digital output isolated no. 2 15 DO3 Digital output isolated no. 3 16 DO4 Digital output isolated no. 4 17 DO5 Digital output isolated no. 5 18 DO6 Digital output isolated no. 6 Please see details about digital inputs DI1-8 and digital outputs DO1-6 in the Common hardware section.

-

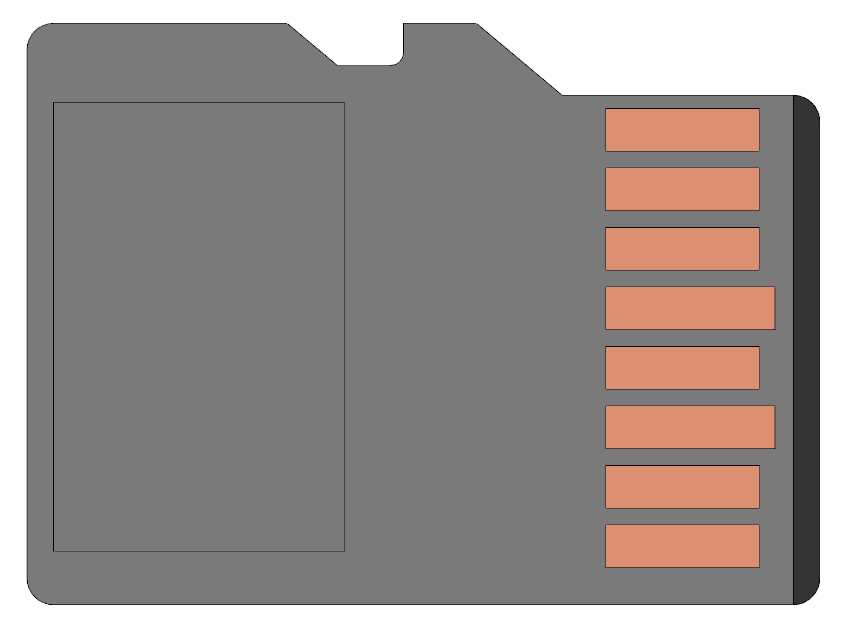

X9 - MicroSD slot

-

It is not primarily recommended to use the microSD slot in devices where significant vibrations are expected. SD card is not included with the "RI" version of servoamplifiers. For more information, see SD cards.

-

X10 - CAN

-

Molex ClikMate 5031490800 - recommended crimping contacts Molex 502579 3

pin # Marking Description 1 CAN-H signal CANH (High) isolated 2 CAN-L signal CANL (Low) isolated 3 CAN GND Iso GND for CAN 4 CAN GND Iso GND for CAN 5 CAN-H signal CANH (High) isolated 6 CAN-L signal CANL (Low) isolated 7 CAN TERM-H termination short input TERM-L – CAN termination 8 CAN TERM-L termination short input TERM-H – CAN termination -

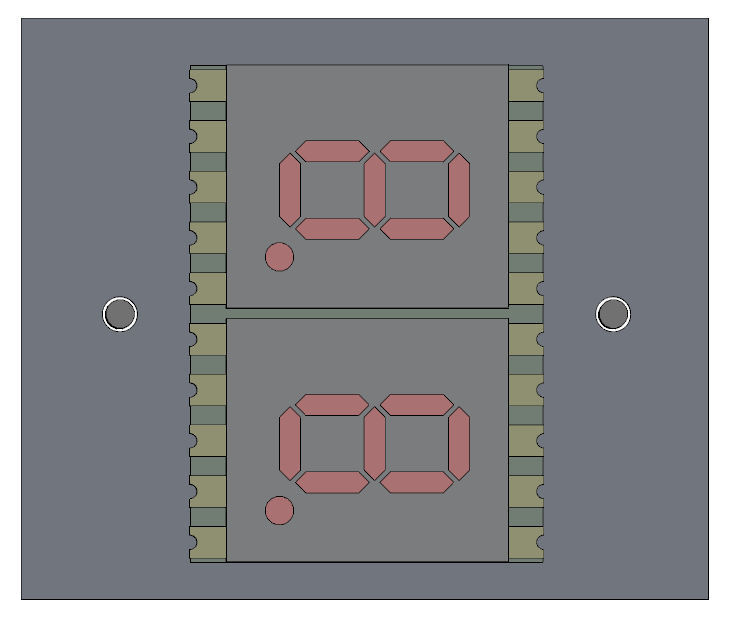

LED display

-

LED display indicates the status of the servoamplifier. See TGZ status indicators for detailed description.

-

status LEDs

-

LED diodes

LED color Status green Servo OK red Servo Error A complete description of the meaning of the status LEDs can be found here: TGZ status indicators

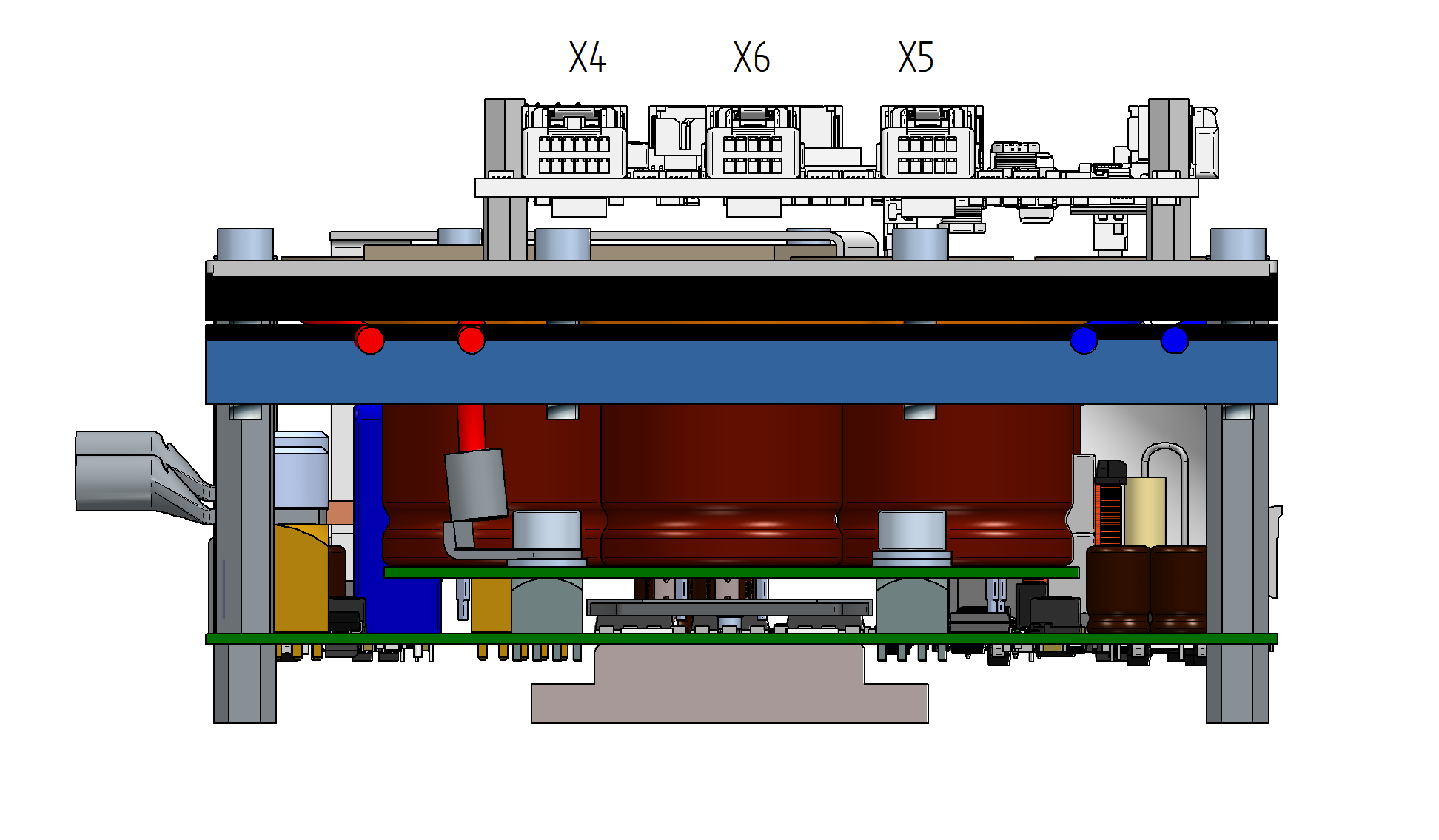

Feedback side view¶

-

X4 - External encoder (FBE)

-

Molex ClikMate 5031491200 - recommended crimping contacts Molex 502579 3

pin # Endat 2.2/SSI/BISS Hiperface DSL Incremental encoder RS422, RS485 1 +12 V DSL+ +12 V - 2 GND DSL- GND - 3 MA+ (CLK+) - B+ TxD+/RxD+ 4 MA- (CLK-) - B- TxD-/RxD- 5 SLO+ (DATA+) FBSEL+ A+ TxD+/RxD+ 6 SLO- (DATA-) FBSEL- A- TxD-/RxD- 7 - FBSEL+ - - 8 - FBSEL- - - 9 ZERO+ - Z+ RxD+ 10 ZERO- - Z- RxD- 11 +5V +5V +5V +5V 12 GND GND GND GND For more information on external feedback, see FBE Feedback.

-

X5 - Feedback axis 1

-

Molex ClikMate 5031491000 - recommended crimping contacts Molex 502579 3

pin # Endat 2.2/SSI/BISS Hiperface DSL Incremental encoder RS422, RS485 1 +12 V DSL+ +12 V +12 V 2 GND DSL- GND GND 3 MA+ (CLK+) - B+ TxD+/RxD+ 4 MA- (CLK-) - B- TxD-/RxD- 5 SLO+ (DATA+) FBSEL+ A+ TxD+/RxD+ 6 SLO- (DATA-) FBSEL- A- TxD-/RxD- 7 - FBSEL+ - - 8 - FBSEL- - - 9 +5V +5V +5V +5V 10 GND GND GND GND For more information regarding Feedback 1, please see Feedback FB1, FB2.

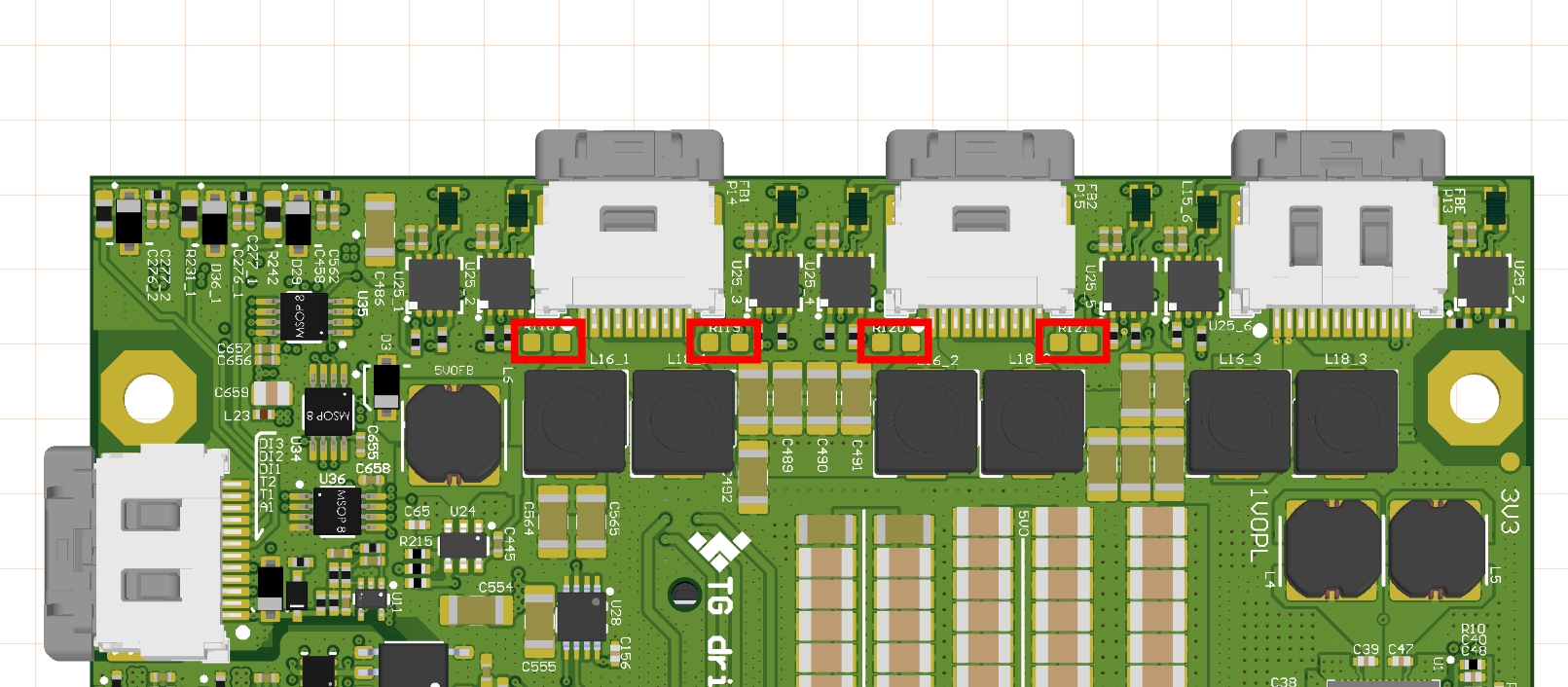

Warning

In order to use Hiperface DSL feedback user must tie pins 5-7 and 6-8 together of the FB1 (and FB2 respectively) connector or assembly appropriate shorting resistors to the control PCB. This applies from batch supplied after 06-2024 onwards, where no internal connection is done on DSL as a standard. Also check whether you have correct firmware uploaded in the device.

-

X6 - Feedback axis 2

-

Molex ClikMate 5031491000 - recommended crimping contacts Molex 502579 3

pin # Endat 2.2/SSI/BISS Hiperface DSL Incremental encoder RS422, RS485 1 +12 V DSL+ +12 V +12 V 2 GND DSL- GND GND 3 MA+ (CLK+) - B+ TxD+/RxD+ 4 MA- (CLK-) - B- TxD-/RxD- 5 SLO+ (DATA+) FBSEL+ A+ TxD+/RxD+ 6 SLO- (DATA-) FBSEL- A- TxD-/RxD- 7 - FBSEL+ - - 8 - FBSEL- - - 9 +5V +5V +5V +5V 10 GND GND GND GND For more information regarding Feedback 1, please see Feedback FB1, FB2.

Warning

In order to use Hiperface DSL feedback user must tie pins 5-7 and 6-8 together of the FB1 (and FB2 respectively) connector or assembly appropriate shorting resistors to the control PCB. This applies from batch supplied after 06-2024 onwards, where no internal connection is done on DSL as a standard. Also check whether you have correct firmware uploaded in the device.

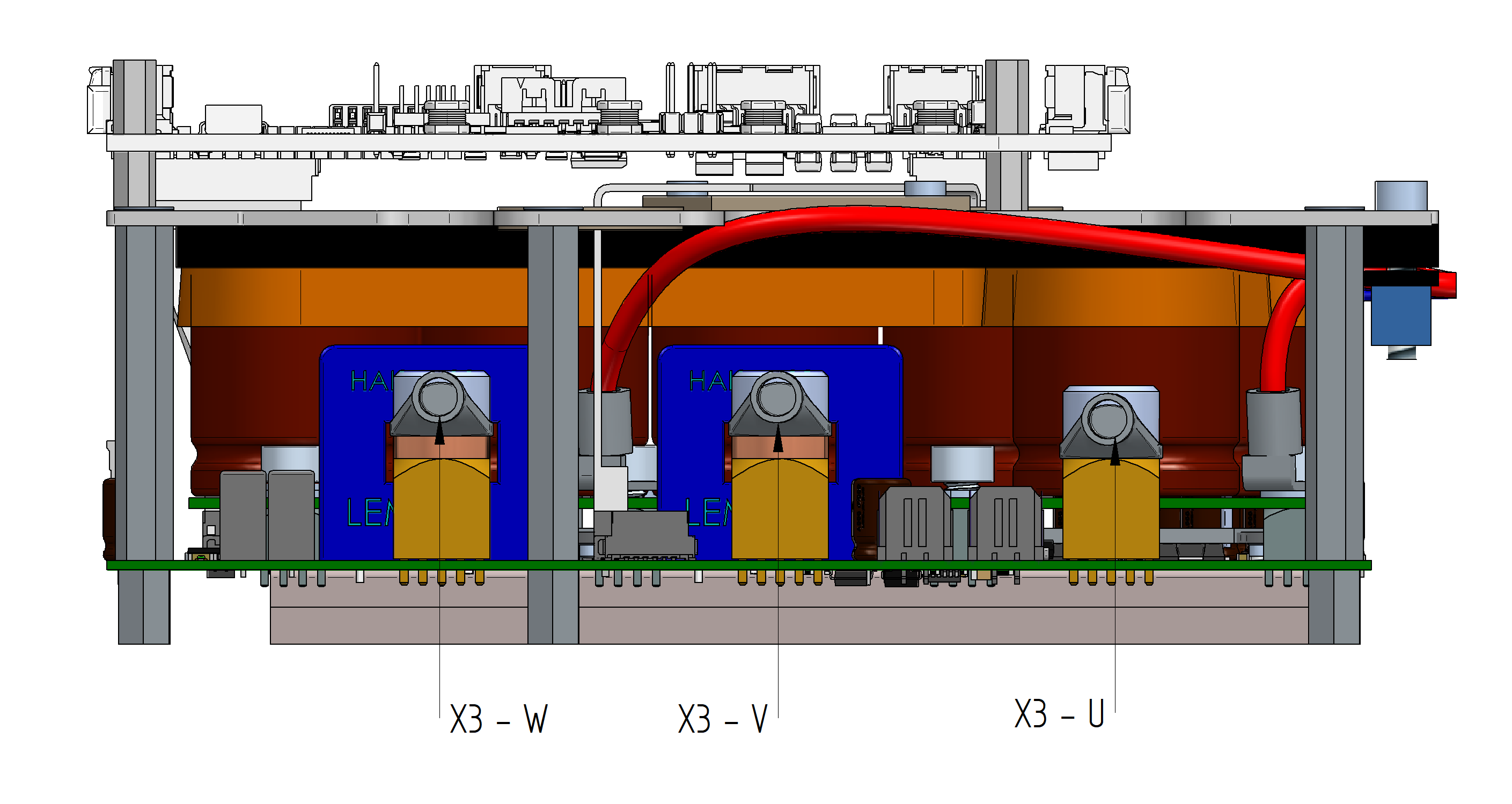

Motor side¶

-

X3 - Motor connector

-

Pressfit M8

Recommended wire cross section 25-35 mm2 (3 - 2 AWG), crimping ring tube for the M8 screw. Recommended crimping ring tube BM 01737.

Wire cross section

The cross section and the length of the cables depends on the type of servomotor, cable and operation of the drive. Please contact your supplier for an exact calculation corresponding to your project.

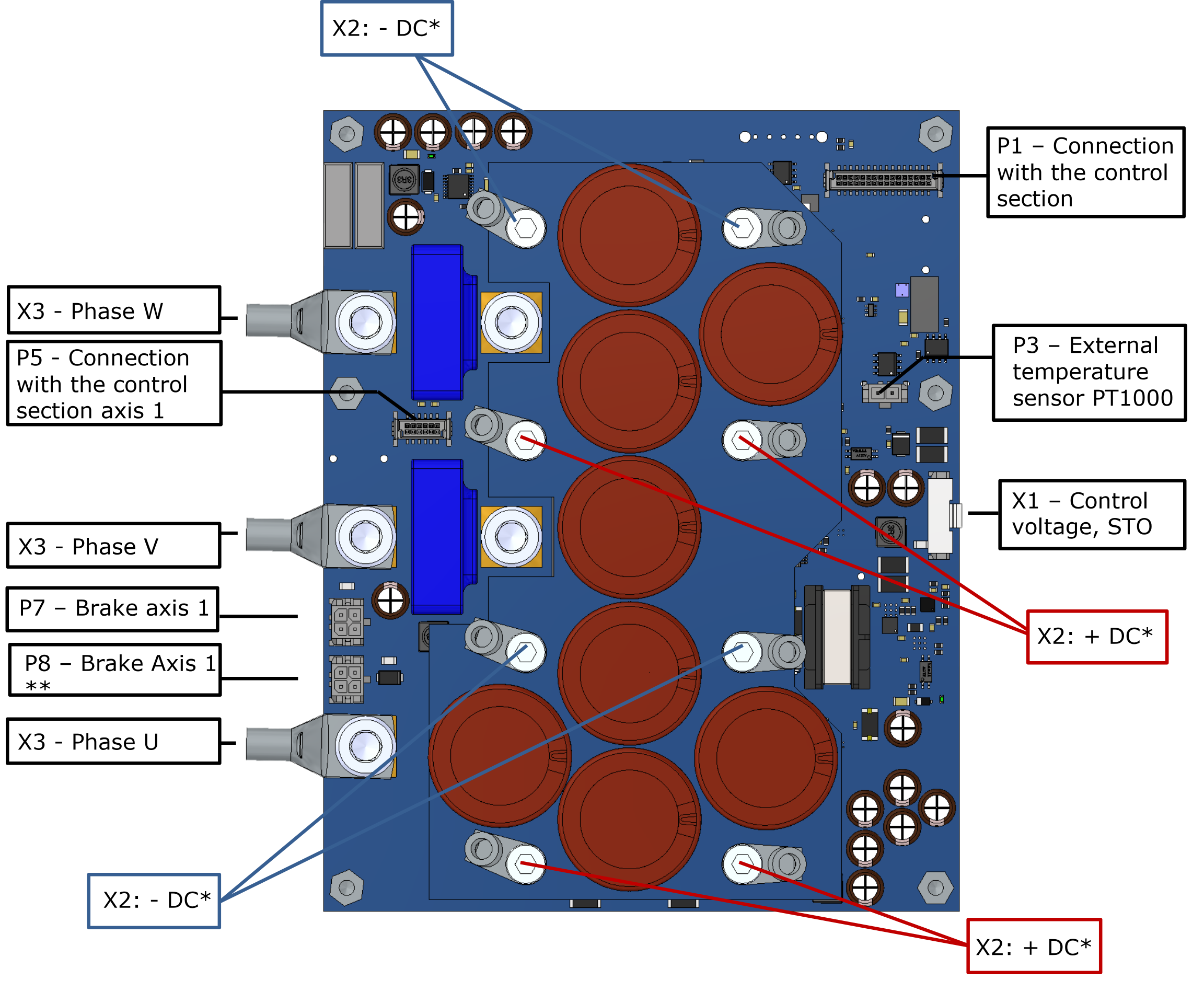

Top view¶

* +DC is marked as VCC and -DC is marked as GND on the PCB silkscreen layer.

** For detailed information about P8 usage please see example schematic.

X2 - Power supply voltage (DCbus)

| Designation / Type | Cable Cross-Section (AWG) | Type and Size of Terminal Lug | Recommended Lug Type | |

|---|---|---|---|---|

| min | max | |||

| DC bus (-DC, +DC) – 4 cables 5 | 8 | 7 | Crimp lug M5, AWG 8 | GS5-10JST |

| DC bus (-DC, +DC) – 8 cables 5 | 12 | 9 | Crimp lug M5, AWG 10 | BM 01325 |

DC bus wire length

Default supplied DCbus wires length is 1 m.

Regenerative braking

In cases when the drive is not powered by a battery (e.g., a Li-ion battery pack), it is necessary for machines with greater kinetic energy to ensure its dissipation, for example, in a resistive element using a chopper unit.

-

X1 - Control supply voltage

-

Molex Micro-Fit 3.0 - 436450500. Recommended crimping contacts Molex 43030. 4

pin # Marking Description AWG 1 VCC +24V DC control supply voltage 19-30 2 VCC_OUT output +24 VDC 19-30 3 GND GND (0 V) 19-30 4 STO_A STO channel A 19-30 5 STO_B STO channel B 19-30 Warning

Pin 2 of connector X1 - "+24 VDC output" must be connected externally to pin 2 of connector P7 (power supply for static brake diagnostics).

Note the orientation of the connector - locking lever on top = pin 1 on the right.

Connector crimps

Match the type of crimps to the selected wire cross section.

-

P7 - Static brake

-

Molex Micro-Fit 3.0 - 430250400. Recommended crimping contacts Molex 43030. 4

pin # Marking Description AWG 1 VCC +24V DC Brake power 19-30 2 VCCD +24V DC Brake diag. power 19-30 3 +BR + Static brake 19-30 4 -BR - Static brake 19-30 P8 connection

Please connect pin 4 of P8 connector according to recommended wiring diagram for static brake to work properly.

Connector crimps

Match the type of crimps to the selected wire cross section.

-

P8 - Static brake

-

Molex Micro-Fit 3.0 - 430250400. Recommended crimping contacts Molex 43030. 4

pin # Marking Description AWG 1 NC No connect 19-30 2 NC No connect 19-30 3 NC No connect 19-30 4 GND 0V control supply voltage 19-30 P8 connection

Please connect pin 4 of P8 connector according to recommended wiring diagram for static brake to work properly.

Connector crimps

Match the type of crimps to the selected wire cross section.

-

P3 - External temperature sensor PT1000

-

Molex Micro-Fit 3.0 - 436500215. Recommended crimping contacts Molex 43030. 4

pin # Marking Description AWG 1 TERM PT1000 sensor 19-30 2 TERM PT1000 sensor 19-30 Polarity

The PT1000 temperature sensor does not have a specified polarity.

Connector crimps

Match the type of crimps to the selected wire cross section.

Procedure for changing feedback type of FB1 and FB2¶

There are 4 positions (R118-R121) for a 0R/0603 resistors that may be used to replace the external connection of FBSEL (pins 5-7 and 6-8 of the FB1 and FB2) on the control board. By default, it is not assembled from batch 06—2024 onwards unless noted otherwise. User can assemble it in order to prevent the need for use the external connections, however keep in mind that once assembled the boards can be used for HiperfaceDSL feedback only. If it is necessary to use a different type of feedback than Hiperface DSL, it is necessary to desolder them from the PCB. Other usable standards are EnDat 2.2, SSI, BISS or Incremental encoder. The feedback function also depends on the uploaded firmware.

-

These types work with modified firmware. It is recommended to always consult with manufacturer about their use. ↩↩

-

Hall sensors must be connected to the digital inputs using a special level shifter. For more information see. Hall converter. ↩↩↩

-

When crimping and connecting the Molex Clik-Mate connectors, follow the Molex Clik-Mate Application Guide. ↩↩↩↩↩↩↩↩↩↩

-

When crimping and connecting the Molex Micro-Fit connectors, follow the Molex Micro-Fit Application Guide. ↩↩↩↩